#gas pipeline repair service

Explore tagged Tumblr posts

Text

Trustworthy Gas Stove Repair Services for Every Household in Bangalore

Gas stoves are quite an essential part of every Indian household, and they provide the basis for day-to-day cooking and preparing meals. Gas stoves, in turn, undergo wear and tear due to use, therefore affordability, really shouldn't be expected. All of this where timely and good service to ensure that domestic workers are safe, efficient, and adhere to their lifetime.

In this blog, we'll discuss the importance of reliable gas stove repair services in India, the troubles faced by dominators, and how to get the gas stove repair service near you that best suits your needs.

What to Look for in a Trustworthy Repair Service

The right service provider for gas stove repair is what would make it an effective and safe repair. The following are the factors to consider:

Experience and Certification

A good service provider should have certified technicians specializing in gas stove repair service. Experience with different brands and models is an added advantage.

Prompt and Efficient Service

A good repair service should be responsive, and it should offer same-day repairs for urgent issues like a gas leak.

Transparent Pricing

Reliable services ensure up-front pricing, and detailed invoices with no additional costs, which are helpful to determine your judgment and decision.

Warranty on Repairs

Services with guarantees on repaired products and replacement parts give confidence about the services as it creates confidence in your work for customers.

Positive Reviews

Online reviews and testimonials may indicate the dependability and professional standards of a service provider. Sometimes word of mouth can be highly appreciable.

Advantages of Professional Gas Stove Repair Services

There are several benefits of hiring professional gas stove repair services:

Safety

A certified technician will assist in doing all repairs safely, thus eliminating chances of gas leaks and fire hazards.

Cost Saving

Minor issues can be mitigated, avoiding costly problems due to timely repairs. This will also reduce your expenditure on buying a new appliance.

Efficiency

A stove that is well-maintained runs like a lion on a safari, consuming less gas with utmost performance.

Long appliance life

Maintenance and repairs may double the life of the appliance, especially the gas stove.

Self-maintenance tips that may prevent frequent visits to the service center

While professional services are essential for major issues, regular maintenance can reduce the need for frequent repairs. Here are some tips to keep your gas stove in good condition:

Check for Gas Leaks

Periodically inspect gas pipes and connections for signs of wear or leaks. Replace damaged parts immediately.

Keep Knobs and Valves Working

Clean and lubricate gas knobs and valves to ensure they are working properly.

Use the Right Cooking Utensils

Avoid using oversized or heavy utensils that may damage the burner or stove surface.

Annual Servicing

Get a professional to inspect and service your gas stove annually to prevent problems from getting worse.

Conclusion

A well-maintained gas stove is important for the smooth functioning of every Indian household.

Whether it's a minor knob issue or a critical gas leak, Rightcliq professional gas cooktop repair services in Bangalore are equipped to handle it all. Invest in reliable services today for a safer and more efficient cooking experience.

Resource: https://rightcliqservices.blogspot.com/2025/01/trustworthy-gas-stove-repair-services.html

#gas stove repair service#expert gas stove repair technician#gas stove repair technician#gas pipeline repair service

0 notes

Text

Why regular plumbing servicing is helpful, and how you can do it yourself.

Your living space reflects your state of mind, pristine works if pristine it seems. Messy works too if that your vibe is. Imagine shut windows, boarded up, what do you think that reflects? Decay; not just mess, Now, mess is when there exist leaks or no electricity. Well, leaks and electricity issues are common place. Let’s quit the meditation on decay and messy states and check into reality. Why is a regular plumbing maintenance important on a regular basis?

Simplifying this,

What are some plumbing grievances that could disrupt your daily routine, and how you could do it yourself, although getting professional plumbing services would be better and it is easy on your pockets too.

Leaks, drainage clogs, water heater hazards, flushing issues and the likes. A regular plumbing maintenance routine would look something this,

Simple routine things if done on a regular could save you from potential water hazards.

Checking water pressure, making sure it is in the normal range.

Checking for leaks, inspecting pipes, shower heads, faucets, valves and taps to check in case there are leaks.

Drainage cleaning, plungers come in handy or perhaps natural solutions like using baking sodas or vinegar to rid of the sheen.

Toilet maintenance, water heater, flush them both to eradicate the sediment accumulated.

Finally, checking the water quality, and taking care of the garbage disposal, since that is the key.

Now you know how to prevent blockages and clogs, issues with the sewer line and drain clogs, this would be real helpful to avoid damages and any other potential plumbing hazards.

But despite this, you encounter any plumbing hazards or issues. Reach out to us to get instant fixes.

Contact: +91 9980806696

Visit: www.instafix.in

#pipe installation services#pipe fitting services#gas pipeline installation services#commercial drain cleaning equipment#drain cleaning berlin#drain cleaning website#drain cleaning and unclogging services definition#water heater repair services near me#water heater installation & repair systems#water heater repair routine maintenance checklist#maintenance routine#routine inspection maintenance#leak detection and repair services#leak detection and repair companies#leak detection and repair system

0 notes

Text

What to Expect from a Professional Gas Stove Service Kollam

If you rely on a gas stove for cooking, keeping it in optimal condition is essential for both safety and efficiency. Over time, gas stoves can encounter various issues, from burner problems to gas leaks, which can affect your cooking experience and may even pose safety risks. Regular servicing by a professional ensures that your gas stove remains in excellent working order. This article explores the advantages of a professional Gas stove service Kollam and what to expect during a standard service.

1. Thorough Inspection and Diagnosis

A professional gas stove service begins with a detailed inspection of the appliance. Technicians examine each part of the stove, including the burners, ignition system, valves, pipes, and gas connections. They look for signs of wear, blockage, or leaks. Diagnosing potential problems early can prevent them from developing into more serious issues. For instance, blocked burners can reduce cooking efficiency and cause uneven heating, while a minor leak can lead to hazardous situations if left unchecked.

Through this diagnostic process, a professional can determine the exact cause of any issues and suggest appropriate solutions.

2. Cleaning and Maintenance of Burners

One of the most common issues with gas stoves is burner clogging. Food particles, grease, and dust can accumulate on the burners over time, reducing the flame's strength and causing uneven heating. During a professional gas stove service Kollam, the technician cleans the burners thoroughly, removing any buildup and debris. This cleaning process helps restore optimal flame output, ensuring even cooking and better heat distribution.

In addition to cleaning the burners, the technician may also adjust the burner heads or replace them if they are too damaged. Regular cleaning as part of a professional service ensures that the gas stove operates smoothly, prolonging its lifespan.

For more: Gas line service company Kollam, Gas pipeline installation Kollam, Gas stove repair Kollam.

3. Gas Leak Detection and Repair

Gas leaks are a critical safety concern in gas stoves. Even a small leak can lead to hazardous consequences if left undetected. Professional gas stove service providers in Kollam are equipped with the necessary tools to detect leaks accurately. Technicians check the gas pipelines, connections, and valves to identify any leaks or loose fittings. If any leaks are found, they will repair or replace the necessary components to eliminate the risk.

In some cases, the technician may also recommend adding a gas leak detector if the stove setup does not already include one. Taking these preventative steps ensures the safety of everyone in the home.

4. Ignition System Inspection and Repair

Many gas stoves today come with automatic ignition systems, which make lighting the stove convenient. However, ignition systems can sometimes fail due to frequent use, worn-out wiring, or exposure to moisture. When a professional technician services a gas stove, they inspect the ignition system, check for any faults, and test its functionality. If necessary, they will repair or replace components of the ignition system to ensure it works correctly. This inspection is particularly important for those who rely on the automatic ignition feature, as a malfunctioning ignition can be both frustrating and unsafe.

5. Valve and Knob Maintenance

Valves and knobs control the flow of gas to the burners, allowing users to adjust the flame strength. Over time, these components can become stiff, hard to turn, or loose, affecting your ability to control the stove effectively. During a professional Gas Stove Service Kollam, technicians examine the valves and knobs, ensuring they are easy to use and function correctly.

The technician may apply lubrication if necessary or replace damaged knobs and valve mechanisms. Properly maintained valves and knobs allow for safe, precise control of the flame and improve your overall cooking experience.

6. Replacement of Worn-Out Parts

Sometimes, certain parts of the gas stove become worn out beyond repair due to regular use, such as burner caps, igniters, or rubber seals. A professional technician can assess whether any components need replacement and provide high-quality parts to restore the stove’s functionality. Replacing worn-out parts not only prevents future breakdowns but also ensures that the gas stove performs at its best.

Using genuine replacement parts provided by a professional service ensures compatibility and durability. Replacing worn-out parts regularly as part of routine maintenance can save you from more significant, costly repairs in the future.

7. Safety Check and Testing

Once the cleaning, repair, and replacement processes are complete, the technician will conduct a final safety check. This includes testing all parts of the stove to ensure that they work seamlessly and there are no safety hazards, such as gas leaks or faulty ignitions. The technician may also provide safety tips for daily stove use and guidance on how to recognize early warning signs of issues.

These final checks and tests give you peace of mind, knowing that your gas stove is in optimal condition and safe for use.

8. Expert Tips for Maintenance and Usage

During a professional gas stove service, technicians often share helpful maintenance tips to ensure the longevity of the stove. They may advise on cleaning techniques, recommend specific products to remove grease buildup, and suggest regular checks for gas line connections. By following their recommendations, you can keep your gas stove in excellent shape and avoid the need for frequent repairs.

Conclusion

A professional Gas Stove Service Kollam provides a comprehensive solution to keep your gas stove functioning smoothly and safely. Regular service not only addresses existing problems but also helps prevent future issues. From thorough inspections to expert cleaning, repair, and testing, each step is designed to ensure that your gas stove performs reliably.

Routine servicing is an investment in both your appliance’s longevity and your household’s safety. With a well-maintained gas stove, you can enjoy efficient and hassle-free cooking for years to come. If it’s been a while since your last service, consider scheduling one soon to ensure your stove is in top condition.

#Gas stove service Kollam#Gas line service company Kollam#Gas pipeline installation Kollam#Gas stove repair Kollam

0 notes

Text

Looking for reliable gas stove service near you? Our expert technicians provide prompt and professional repair, maintenance, and installation services to keep your gas stove running safely and efficiently. From leak detection to burner issues, we handle it all with quality and care. Contact us for trusted local gas service!

#Gas stove repair in Dehradun#Home gas service Dehradun#Emergency gas service near me#Gas cylinder delivery Dehradun#LPG gas refill Dehradun#Gas pipeline installation Dehradun#Gas leakage repair service Dehradun

0 notes

Text

Gas Line Backfill Near Me

With Mc Queen Gas Inspection Services, you can be sure that your gas line is both safe and reliable. Our knowledgeable staff specialises in "Gas Line Backfill Near Me," offering exact backfilling and comprehensive inspections to stop leaks and guarantee peak performance. Contact us today for all your gas inspection and backfill needs! Call now: 1 (858) 923-7105.

#Gas Inspection Services San Diego#Gas Pipeline Inspection San Diego#Gas Company in Riverside CA#Socal Gas Company Riverside CA#Gas Company Orange County#SDG&E#SDG&E Gas Backfill#Socal Gas Backfill#SDG&E Gas Pipeline Inspections#Gas Line Backfill Near Me#Gas Services Near Me#Gas Line Service#Gas Service Company#Gas Line Company#Southern Cal Gas Company#Gas Pipe Installation#Gas Installation Service#Gas Pipe Repair Near Me#Gas Piping Inspection#Gas Pipeline Inspection#Veriforce Inspection#Gas Line Inspection Near Me

0 notes

Text

Propane and Natural Gas Services in South Florida

When it comes to energy costs, propane or natural gas is typically a more affordable and reliable option than electricity. Our technicians at Reliable Power Systems offer natural gas and propane services to South Florida homeowners. Whether you want to add a grill to your back patio or need to hook up a gas-powered dryer, our team is ready to help. Contact us today and schedule an appointment for gas services in South Florida and the Florida Gulf.

0 notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

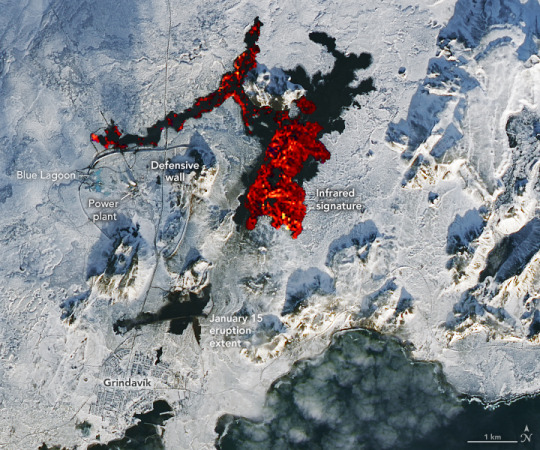

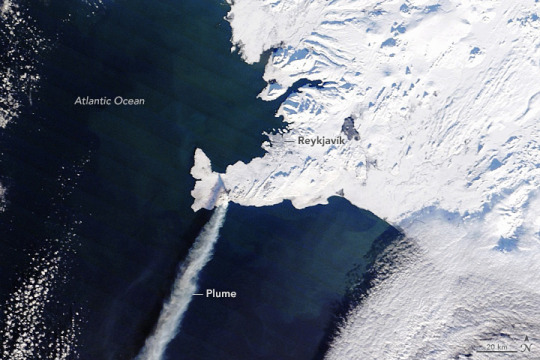

Another Eruption in Iceland

"After a lull in activity, fresh lava has once again poured from the Reykjanes peninsula in southwestern Iceland.

The latest eruption—the third in the region since December 2023—began early on February 8, 2024, with lava spraying up to heights of 80 meters (260 feet) along a 3-kilometer (1.8-mile) long fissure near Mount Sýlingarfell. The small peak is north of the fishing village Grindavík and east of the Svartsengi power station and Blue Lagoon geothermal spa.

The image above was acquired on February 10, 2024, by the OLI-2 (Operational Land Imager-2) on Landsat 9. Infrared and visible observations (bands 7-6-3) have been overlain on a natural-color image to help distinguish the heat signature of the lava. Still recent but cooler lava expelled near Grindavík in January appears black.

The topography around the fissure meant that much of the fresh lava flowed east into unpopulated areas rather than south toward Grindavík. Some lava also flowed west into the vicinity of the power plant and spa.

Earthen defensive walls protected both facilities, though lava did burn through a key hot water pipeline and two roads. According to the Icelandic National Broadcasting Service RÚV, authorities are in the process of restoring hot water to homes in the area after conducting repairs on the pipeline.

About seven hours after the eruption began, the MODIS (Moderate Resolution Imaging Spectroradiometer) on NASA’s Terra satellite captured this image of a plume of gas and ash streaming to the southwest. This eruption was effusive—not explosive like the Eyjafjallajökull eruption in 2010—and the plume contained minimal ash, so it did not cause any disruptions to either domestic or international flights.

Volcanic plumes like the one shown here typically contain water vapor, sulfur dioxide, carbon dioxide, and small amounts of other volcanic gases. Researchers from the Icelandic Met Office and the University of Iceland have noted that, at times, magma has interacted with groundwater, adding to the amount of water vapor in the plume. The TROPOMI (Tropospheric Monitoring Instrument) on the Sentinel-5 Precursor missionobserved sulfur dioxide (SO2) within the plume, Michigan Tech volcanologist Simon Carn noted on X.

After the initial burst of activity on February 8, the intensity of the eruption faded. In an update on February 9, the Icelandic Met Office reported that seismic sensors had stopped detecting volcanic tremors and that a recent drone flight showed no activity over the eruption site—signs that the latest eruption was ending.

However, on February 12, the agency reported that the land surface above an underground magma reservoir near Svartsengi had again begun to swell by 0.5 to 1 centimeters per day, a rate similar to what was observed prior to other recent eruptions. “It is therefore highly likely that the cycle continues in a few weeks with another dyke propagation and a volcanic eruption,” the agency said."

NASA Earth Observatory image by Lauren Dauphin, using MODIS data from NASA EOSDIS LANCE and GIBS/Worldview. Story by Adam Voiland.

8 notes

·

View notes

Text

Download MS Blind Flange PDF with Specifications and Uses

MS Blind Flanges (Mild Steel Blind Flanges) are integral components used to seal the ends of pipelines in industrial applications. They are designed to block off flow, allowing for maintenance, testing, or future pipeline expansions.

For complete technical specifications, you can download the MS Blind Flange PDF, which includes dimensions, pressure ratings, and material properties.

What is an MS Blind Flange?

An MS Blind Flange is a solid disk-shaped plate without a bore. It is bolted to the pipe to terminate flow, ensuring that sections of the pipeline remain sealed. This makes them ideal for temporary or permanent closure of piping systems.

Key Features of MS Blind Flanges:

Made from Mild Steel (MS), ensuring durability and affordability.

Available in multiple pressure ratings, including 150#, 300#, 600#, and higher.

Compliant with international standards, such as ASME, ANSI, and IS.

Used in various industries, including oil & gas, power plants, chemical processing, and water treatment.

Specifications of MS Blind Flanges

Understanding the technical specifications of MS Blind Flanges is crucial for selecting the right type for your industrial needs.

1. Material Composition

Mild Steel (MS): Offers strength and cost-effectiveness.

Galvanized Coating (Optional): Provides corrosion resistance.

Custom Fabrication: Available for specialized requirements.

2. Pressure Ratings

ANSI 150# – Low-pressure applications.

ANSI 300# to 600# – Medium to high-pressure pipelines.

ANSI 900# and above – Used in extreme industrial conditions.

3. Dimensions & Standard Sizes

Below is a reference chart of standard MS Blind Flange sizes:Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts1/2"901541"1251942"1501944"2301986"2802288"34522810"405251212"485251214"535291216"595291618"635321620"6853220

Applications of MS Blind Flanges

MS Blind Flanges are widely used across various industries due to their sealing efficiency and ability to handle high-pressure environments.

1. Oil & Gas Industry

Used in pipelines, refineries, and offshore drilling platforms.

Ensures safe isolation during maintenance and testing.

2. Water Treatment Plants

Helps in isolating pipeline sections for repair work.

Used in water distribution systems.

3. Power Generation

Used in steam transmission and cooling water pipelines.

Provides secure pipeline closure.

4. Chemical Processing Plants

Helps in handling hazardous chemicals and gases.

Provides corrosion-resistant sealing solutions.

5. Construction & Infrastructure

Used in HVAC systems, drainage, and plumbing networks.

Ensures safe termination of unused pipelines.

6. Marine & Shipbuilding

Used in ship fuel pipelines and seawater distribution.

Ensures safe handling of high-pressure liquids.

Advantages of MS Blind Flanges

MS Blind Flanges offer several benefits, making them essential in industrial piping systems.

1. High Durability

Made from strong mild steel, ensuring long service life.

2. Leak Prevention

Completely seals off pipelines, preventing leaks and contamination.

3. Cost-Effective Solution

Affordable compared to stainless steel and alloy alternatives.

4. Easy Installation & Removal

Can be bolted or unbolted for maintenance or expansion.

5. Customization Available

Available in different coatings, pressure ratings, and dimensions.

Where to Download the MS Blind Flange PDF?

For complete MS Blind Flange specifications, material properties, and technical drawings, download the MS Blind Flange PDF from Udhhyog, a trusted supplier in Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

Top MS Blind Flange Suppliers:

Udhhyog (Delhi) – Leading supplier of industrial pipe fittings.

B2B Industrial Marketplaces – Online sources for bulk orders.

Local Distributors – Available in major industrial cities.

Conclusion

MS Blind Flanges play a crucial role in sealing, pressure testing, and pipeline safety. Whether used in oil & gas, chemical plants, or water treatment facilities, MS Blind Flanges provide a reliable and cost-effective solution.

For premium MS Blind Flanges, trust Udhhyog, your leading supplier in North India.

#MSBlindFlange#MildSteelFlange#IndustrialFittings#Pipeline#FlangeTypes#Udhhyog#MetalFabrication#Engineering#Welding#Manufacturing#FlangeSpecifications

0 notes

Text

Download MS Blind Flange PDF with Specifications and Uses

MS Blind Flanges (Mild Steel Blind Flanges) are integral components used to seal the ends of pipelines in industrial applications. They are designed to block off flow, allowing for maintenance, testing, or future pipeline expansions.

For complete technical specifications, you can download the MS Blind Flange PDF, which includes dimensions, pressure ratings, and material properties.

What is an MS Blind Flange?

An MS Blind Flange is a solid disk-shaped plate without a bore. It is bolted to the pipe to terminate flow, ensuring that sections of the pipeline remain sealed. This makes them ideal for temporary or permanent closure of piping systems.

Key Features of MS Blind Flanges:

Made from Mild Steel (MS), ensuring durability and affordability.

Available in multiple pressure ratings, including 150#, 300#, 600#, and higher.

Compliant with international standards, such as ASME, ANSI, and IS.

Used in various industries, including oil & gas, power plants, chemical processing, and water treatment.

Specifications of MS Blind Flanges

Understanding the technical specifications of MS Blind Flanges is crucial for selecting the right type for your industrial needs.

1. Material Composition

Mild Steel (MS): Offers strength and cost-effectiveness.

Galvanized Coating (Optional): Provides corrosion resistance.

Custom Fabrication: Available for specialized requirements.

2. Pressure Ratings

ANSI 150# – Low-pressure applications.

ANSI 300# to 600# – Medium to high-pressure pipelines.

ANSI 900# and above – Used in extreme industrial conditions.

3. Dimensions & Standard Sizes

Below is a reference chart of standard MS Blind Flange sizes:Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts1/2"901541"1251942"1501944"2301986"2802288"34522810"405251212"485251214"535291216"595291618"635321620"6853220

Applications of MS Blind Flanges

MS Blind Flanges are widely used across various industries due to their sealing efficiency and ability to handle high-pressure environments.

1. Oil & Gas Industry

Used in pipelines, refineries, and offshore drilling platforms.

Ensures safe isolation during maintenance and testing.

2. Water Treatment Plants

Helps in isolating pipeline sections for repair work.

Used in water distribution systems.

3. Power Generation

Used in steam transmission and cooling water pipelines.

Provides secure pipeline closure.

4. Chemical Processing Plants

Helps in handling hazardous chemicals and gases.

Provides corrosion-resistant sealing solutions.

5. Construction & Infrastructure

Used in HVAC systems, drainage, and plumbing networks.

Ensures safe termination of unused pipelines.

6. Marine & Shipbuilding

Used in ship fuel pipelines and seawater distribution.

Ensures safe handling of high-pressure liquids.

Advantages of MS Blind Flanges

MS Blind Flanges offer several benefits, making them essential in industrial piping systems.

1. High Durability

Made from strong mild steel, ensuring long service life.

2. Leak Prevention

Completely seals off pipelines, preventing leaks and contamination.

3. Cost-Effective Solution

Affordable compared to stainless steel and alloy alternatives.

4. Easy Installation & Removal

Can be bolted or unbolted for maintenance or expansion.

5. Customization Available

Available in different coatings, pressure ratings, and dimensions.

Where to Download the MS Blind Flange PDF?

For complete MS Blind Flange specifications, material properties, and technical drawings, download the MS Blind Flange PDF from Udhhyog, a trusted supplier in Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

Top MS Blind Flange Suppliers:

Udhhyog (Delhi) – Leading supplier of industrial pipe fittings.

B2B Industrial Marketplaces – Online sources for bulk orders.

Local Distributors – Available in major industrial cities.

Conclusion

MS Blind Flanges play a crucial role in sealing, pressure testing, and pipeline safety. Whether used in oil & gas, chemical plants, or water treatment facilities, MS Blind Flanges provide a reliable and cost-effective solution.

For premium MS Blind Flanges, trust Udhhyog, your leading supplier in North India.

#MSBlindFlange#MildSteelFlange#IndustrialFittings#Pipeline#FlangeTypes#Udhhyog#MetalFabrication#Engineering#Welding#Manufacturing#FlangeSpecifications

0 notes

Text

Download MS Blind Flange PDF with Specifications and Uses

MS Blind Flanges (Mild Steel Blind Flanges) are integral components used to seal the ends of pipelines in industrial applications. They are designed to block off flow, allowing for maintenance, testing, or future pipeline expansions.

For complete technical specifications, you can download the MS Blind Flange PDF, which includes dimensions, pressure ratings, and material properties.

What is an MS Blind Flange?

An MS Blind Flange is a solid disk-shaped plate without a bore. It is bolted to the pipe to terminate flow, ensuring that sections of the pipeline remain sealed. This makes them ideal for temporary or permanent closure of piping systems.

Key Features of MS Blind Flanges:

Made from Mild Steel (MS), ensuring durability and affordability.

Available in multiple pressure ratings, including 150#, 300#, 600#, and higher.

Compliant with international standards, such as ASME, ANSI, and IS.

Used in various industries, including oil & gas, power plants, chemical processing, and water treatment.

Specifications of MS Blind Flanges

Understanding the technical specifications of MS Blind Flanges is crucial for selecting the right type for your industrial needs.

1. Material Composition

Mild Steel (MS): Offers strength and cost-effectiveness.

Galvanized Coating (Optional): Provides corrosion resistance.

Custom Fabrication: Available for specialized requirements.

2. Pressure Ratings

ANSI 150# – Low-pressure applications.

ANSI 300# to 600# – Medium to high-pressure pipelines.

ANSI 900# and above – Used in extreme industrial conditions.

3. Dimensions & Standard Sizes

Below is a reference chart of standard MS Blind Flange sizes:Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts1/2"901541"1251942"1501944"2301986"2802288"34522810"405251212"485251214"535291216"595291618"635321620"6853220

Applications of MS Blind Flanges

MS Blind Flanges are widely used across various industries due to their sealing efficiency and ability to handle high-pressure environments.

1. Oil & Gas Industry

Used in pipelines, refineries, and offshore drilling platforms.

Ensures safe isolation during maintenance and testing.

2. Water Treatment Plants

Helps in isolating pipeline sections for repair work.

Used in water distribution systems.

3. Power Generation

Used in steam transmission and cooling water pipelines.

Provides secure pipeline closure.

4. Chemical Processing Plants

Helps in handling hazardous chemicals and gases.

Provides corrosion-resistant sealing solutions.

5. Construction & Infrastructure

Used in HVAC systems, drainage, and plumbing networks.

Ensures safe termination of unused pipelines.

6. Marine & Shipbuilding

Used in ship fuel pipelines and seawater distribution.

Ensures safe handling of high-pressure liquids.

Advantages of MS Blind Flanges

MS Blind Flanges offer several benefits, making them essential in industrial piping systems.

1. High Durability

Made from strong mild steel, ensuring long service life.

2. Leak Prevention

Completely seals off pipelines, preventing leaks and contamination.

3. Cost-Effective Solution

Affordable compared to stainless steel and alloy alternatives.

4. Easy Installation & Removal

Can be bolted or unbolted for maintenance or expansion.

5. Customization Available

Available in different coatings, pressure ratings, and dimensions.

Where to Download the MS Blind Flange PDF?

For complete MS Blind Flange specifications, material properties, and technical drawings, download the MS Blind Flange PDF from Udhhyog, a trusted supplier in Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

Top MS Blind Flange Suppliers:

Udhhyog (Delhi) – Leading supplier of industrial pipe fittings.

B2B Industrial Marketplaces – Online sources for bulk orders.

Local Distributors – Available in major industrial cities.

Conclusion

MS Blind Flanges play a crucial role in sealing, pressure testing, and pipeline safety. Whether used in oil & gas, chemical plants, or water treatment facilities, MS Blind Flanges provide a reliable and cost-effective solution.

For premium MS Blind Flanges, trust Udhhyog, your leading supplier in North India.

#MSBlindFlange#MildSteelFlange#IndustrialFittings#Pipeline#FlangeTypes#Udhhyog#MetalFabrication#Engineering#Welding#Manufacturing#FlangeSpecifications

0 notes

Text

gas pipeline repair service

0 notes

Text

The Guide to Small Ball Valves: Types, Applications, Tips.

When it comes to fluid control in compact systems, small ball valves, mini ball valves, and miniature ball valves are indispensable components. These valves are designed for precision, durability, and space efficiency, making them ideal for industries ranging from plumbing and HVAC to chemical processing and manufacturing. In this comprehensive guide, we’ll explore the key features, types, materials, and applications of small ball valves, along with tips for selecting the right valve for your needs.

—

What is a Small Ball Valve

A small ball valve is a quarter-turn valve that uses a hollow, perforated ball to control fluid flow. When the valve handle is turned 90 degrees, the ball rotates to align its bore with the pipeline (open position) or block it completely (closed position). These valves are characterized by their compact size, lightweight design, and ease of operation, making them perfect for tight spaces or applications requiring frequent adjustments.

Key advantages of small ball valves include:

- Leak-proof sealing for reliable performance. - Quick shutoff with minimal torque. - Versatility in handling liquids, gases, and corrosive media. - Low maintenance due to simple construction.

—

Types of Small Ball Valves

Small ball valves are available in various designs to suit specific applications. Below are the most common types:

1. Thread Ball Valve

A thread ball valve features threaded ends (NPT, BSPP, or BSPT) for easy installation in pipelines without welding. These valves are widely used in residential plumbing, compressed air systems, and low-pressure industrial setups.

2. Flange Ball Valve

Flange ball valves have flanged ends for bolted connections, ideal for high-pressure or large-diameter systems. They are common in oil and gas, water treatment, and chemical industries.

3. 2 PC Ball Valve vs. 3 PC Ball Valve

- 2 PC ball valves consist of two main body pieces, offering a balance between cost and serviceability. - 3 PC ball valves feature three separable body sections, enabling easy disassembly for cleaning or repair without removing the valve from the pipeline.

4. Floating Ball Valve

In a floating ball valve, the ball is held in place by compression from the valve seats. This design is cost-effective and suitable for low-to-medium pressure applications.

—

Material Choices for Small Ball Valves

The valve material impacts its durability, corrosion resistance, and compatibility with fluids. Popular options include:

1. Stainless Steel Ball Valve

Stainless steel ball valves (e.g., SS304, SS316) excel in corrosive environments, such as chemical processing, marine applications, or food-grade systems.

2. Carbon Steel Ball Valve

Carbon steel ball valves are robust and economical, ideal for high-temperature and high-pressure systems in oil refineries or power plants.

3. Forged Steel Ball Valve

Forged steel ball valves are manufactured through forging, resulting in superior strength and resistance to extreme conditions. They are commonly used in heavy-duty industrial applications.

—

Applications of Small Ball Valves

- Plumbing and HVAC: Regulating water flow in residential or commercial systems. - Chemical Processing: Handling aggressive fluids with stainless steel or PTFE-lined valves. - Automotive: Fuel and coolant control in compact engine systems. - Pharmaceuticals: Ensuring sterile fluid transfer with sanitary ball valves. - Agriculture: Irrigation and fertilizer distribution.

—

How to Choose the Right Small Ball Valve

1. Pressure and Temperature Ratings: Ensure the valve meets your system’s operational limits. 2. Connection Type: Select threaded, flanged, or welded ends based on installation requirements. 3. Material Compatibility: Match the valve body and seal materials to the fluid type (e.g., PTFE seals for chemicals). 4. Valve Size: Confirm the port size (e.g., ¼” to 2”) matches your pipeline dimensions. 5. Certifications: Look for industry standards like API, ANSI, or ISO for quality assurance.

—

FAQs About Small Ball Valves

Q: What’s the difference between a mini ball valve and a standard ball valve

A: Mini ball valves are smaller in size (typically under 1” diameter) and designed for low-flow or precision applications, whereas standard ball valves cater to larger systems.

Q: Can a stainless steel ball valve handle seawater

A: Yes, SS316 stainless steel valves offer excellent corrosion resistance in marine environments.

Q: When should I choose a 3 PC ball valve over a 2 PC design

A: Opt for a 3 PC ball valve if frequent maintenance or cleaning is required, as it allows easy access to internal components.

—

Conclusion

From thread ball valves in household plumbing to flange ball valves in industrial pipelines, small ball valves play a critical role in modern fluid control systems. By understanding the differences between floating ball valves, stainless steel ball valves, and forged steel ball valves, you can make informed decisions to optimize performance and longevity. Whether you need a miniature ball valve for a lab setup or a heavy-duty carbon steel ball valve for a refinery, prioritize quality materials, proper sizing, and compliance with industry standards.

Need a reliable small ball valve supplier, Contact Chinese NSW valve manufacturer experts today to find the perfect valve for your application.

#ball valve manufacturers in india#ball valve suppliers#ball valve#small ball valve#mini ball valve#china ball valve manufacturer#ball valve manufacturer#ball valve factory#ball valve supplier

0 notes

Text

Comprehensive Gas Stove Repair Kollam

A gas stove is a staple asset in nearly every home, and in Kollam, where the preparation of a home-cooked meal is a norm, it is more so. Unfortunately, even some of the best gas stoves on the market will develop some problems that will need some repair work. When it comes to repair as an incident of use how minor or how major that may be, Gas stove repair Kollam is a critical process for safety and convenience. This article covers all fundamental areas of gas stove repair Kollam, including the need to seek Gas stove service Kollam from a professional, some frequent problems, and ways in which you could care for your gas stove.

Why Professional Gas Stove Repair Matters

The fact is that while being rather efficient and convenient for use, gas stoves are potentially dangerous appliances the usage of which requires proper maintenance and timely repairs. Also, a gas stove if not well maintained poses considerable danger as it is a source of gas leakages, which may result in fire or explosion. That is why it is wise to consult a professional repairman as soon as you begin to see your gas stove malfunctioning.

Kollam-based technicians know the best way to identify and solve most of the gas stove issues and are armed with the right tools. They guarantee optimized work to avoid subsequent damages and work with safety measures to guarantee safety. In addition, most of the professional gas stove repair Kollam services have their warranties that assure the client that the problem will be fixed.

Here, you will find the most frequent problems people experience with gas stoves and how you can solve them:

Among the common problems that gas stoves experience are those that warrant the attention of a Gas pipeline installation Kollam professional. Below are some common issues and their typical solutions:

1. Ignition Problems:

Among them, the most frequent problem is the inability of its ignition in the case of gas stoves. This can occur when the cup assembly has a faulty ignition switch, the burner orifice is blocked, or when the spark electrode is impaired. A competent professional can make the burners to be washed, the wiring to be checked, or even change those parts that have developed a problem to ensure that they can ignite appropriately.

2. Weak Flame:

Your gas stove can give a laser flame if the burners are clogged or if there is a minimum supply of gas. This is rather a dangerous issue that may suggest the presence of a gas leak or some other issues. The repair expert will check the gas line, attend to the burner, and ensure that the pressure of the gas is correct.

3. Gas Odor:

If one detects a smell of the gas in the kitchen then this is something that one should not ignore. This could point to a leakage of gas, a compound that has the capability of causing a fire outbreak shortly. In case you get a smell of the gas, then you should turn off the stove and seek the help of a specialist. The technician will find and correct the leak and make sure that you are safe.

4. Uneven Heating:

For a gas stove that has difficulty in distributing heat, it can be quite difficult to cook food to the required temperatures. This issue might be due to a bad position of the burner or / with a gas flow issue. A gas stove repair Kollam professional is capable of changing the position of the burner and also inspecting the gas flow so that the heat is evenly distributed.

5. Noisy Burner:

A noisy burner can cause (pain in the neck) and can also be a sign of some sort of a fault with the gas/air mixture. They include: This can be rectified by either cleaning the burner or adjusting the air shutter. The noise can be investigated by a technician and can be treated to bring back the ability to run quietly.

When to Call for Professional Help

Some of the minor gas stove problems can however be fixed with simple remedies but it is important to know the time to call in a Gas line service company Kollam. Here are some situations where expert assistance is necessary:

Persistent Ignition Problems: If your stove has a problem of not lighting up as supposed then it is time to call a professional.

Gas Leaks: In case of a sly of the gas, he or she should call a technician.

Burner Issues: If the fire is weak, the heating is irregular, or the burners are noisy they should be checked by an expert.

Unexplained Stove Malfunctions: In cases where you cannot identify or solve any issue you should seek the services of a specialist.

Tips for Maintaining Your Gas Stove

It is extremely important to service the gas stove to ensure that it is in proper working condition always. Here are some tips to help you maintain your gas stove and avoid frequent repairs:

1. Clean the Burners Regularly:

This was good advice, though I also learned to clean the burners after each use. This helps to avoid debris and grease accumulation on the surface of the burner, which may in return cause clogging of the burner holes in the process.

2. Check the Ignition System:

Check that no debris is present in the ignition switch and the spark electrode devices. If the stove does not ignite, then it is necessary to check these details yourself without a technician.

3. Monitor Gas Connections:

It is also important to remember to periodically inspect the gas hose and its connections for symptoms of prior use or possible wear and tear. Any cracks and leakage which may be seen should be repaired or replaced as soon as possible.

4. Schedule Professional Inspections:

Of course, if your gas stove is in relatively good condition, it still does not hurt to consult a specialist at least once in a while. They can establish when there is a likelihood of the formation of incorporating complicated and problematic aspects.

5. Use the Stove Properly:

It is advisable always to adhere to the instructions that come with your specific brand of gas stove. Do not use the stove for heating, drying, or for any such purposes, and do not place too many things on the burners.

Conclusion

Gas stoves are commonly used and found in nearly every home in Kollam and therefore the appliances must be well maintained. Regardless of the ignition issues, weak flames or even gas leaks Individuals should hire experts to work on any of these problems. Thus if the common problems associated with stoves are well understood and regular checkups and cleaning are done then you are assured of having the appliance in your home for many years. If there exists a problem that you cannot solve alone you must call for the services of a professional in gas stove repair Kollam.

#gas stove repair Kollam#Gas pipeline installation Kollam#Gas stove service Kollam#Gas line service company Kollam

1 note

·

View note

Text

Best Gas Pipeline Installation Technician in Coimbatore

Sri Baghyalakshmi Gas Pipeline Installations are the Best Gas Pipeline Installation Technician in Coimbatore, offering reliable and professional services for residential, commercial, and industrial gas pipeline needs. With a strong reputation for safety, precision, and high-quality workmanship, our expert team ensures seamless gas pipeline installation, maintenance, and repair. We use top-grade materials and advanced techniques to guarantee leak-proof and efficient gas connections. Whether you need a new pipeline setup or an upgrade to your existing system, Sri Baghyalakshmi Gas Pipeline Installations delivers trusted solutions with a commitment to excellence and customer satisfaction in Coimbatore.

Visit: https://maps.app.goo.gl/nk5PQHniYhRXbgzs5

0 notes

Text

When it comes to finding out the flow rate of any liquid and gas through a pipeline, the use of a flow metre is paramount. A flow metre not only helps to identify the rate of fluid flow but also serves as a critical tool for monitoring system performance. It ensures accurate measurement for process control and optimization.

That’s why flow metres are becoming a popular choice in the industry. However, like any other mechanical machine, equipment, or tool; the flow metre is also subject to regular inspection and care. Otherwise, its ability to gauge the flow of liquid and gas can be impaired which can lead to bigger problems. So, it makes sense to read this helpful article written with the help of the biggest Flow Metre Supplier Dubai. All the information mentioned in the content below is based on industrial facts. At the end of the content below, you will find yourself better prepared to make an informed decision about your flow metres. A brief overview has also been given about the best Level Transmitter Supplier in Dubai. So, let’s start.

5 common flow metre problems & possible solutions

If you are wondering why engineers, process managers, and technicians rely heavily on the best Flow Metre Supplier in Dubai, this is because they know the best supplier always supplies the top-notched flow metres that show precise readings with 100% accuracy, reliability, and durability. Most importantly, they need the least maintenance and regular inspection, ensuring smooth operation for many years. However, over time after consistent use, flow metres start showing incorrect readings due to many reasons. That’s the situation when the following information will come to help you immensely. Here we go.

Stuck Flow Metre

If your flow metre has stopped working completely or got jammed then might be possible that an internal blockage has occurred. A blocked flow metre will certainly show you inaccurate and inconsistent readings. The solution is the complete overhauling and service of the flow metre.

Sudden Heavy Change in the Reading

Are you scratching your head wondering why there is a sudden change in the reading of the flow metre? Well, there can be many reasons including unexpected changes in the fluid due to sudden fluctuations in the pressure or temperature to the viscosity of the flowing material. Huge and sudden changes in the flow rate sometimes can fall outside of the instrument’s calibrated range which might further result in permanent damage in the flow metre. Having it repaired or replaced with a new flow metre by a professional is the only possible solution.

Consistent Fluctuation in Reading

Let’s not forget that fluids like water & chemicals often carry debris, dust, and dirt with them. Plus, these fluids and even gases stimulate some kind of reaction with the surface of flow metres. Over time this reaction results in the development of some kind of carbon or rust that prevents the sensor from gauging the reading. This situation is often called sensor fouling. There are four types of sensor fouling such as scaling, sludge, rust, and slime. Internal cleaning and sensitization can be the effective solution.

#Water Meter Supplier In Dubai#flow meter suppliers in saudi arabia#flow meter supplier in dubai#flow meter suppliers in iraq#tube fittings suppliers in saudi arabia

0 notes